Products

-

10P WAter cooled chiller

Features: The new KTD series industrial chiller is mainly suitable for the plastic industry, which can accurately control the temperature of the plastic molding mold to shorten the molding cycle and accelerate the product styling; The series uses the principle of cold and heat exchange for cooling, which can be quickly cooled and temperature control is stable. It is not affected by environmental factors and is an indispensable configuration equipment in modern industry.

-

Double Glazed Crusher

The whole machine adopts high hardness steel template, and is solid and durable;

Double glazed on all sides into the hopper, low noise;

Shaft made of special material processing, not easily deformed;

Cutter use SKD11 alloy steel, high strength, toughness, and so prone to breaking;

Feeding hopper, cutter and filter can be separated with easy disassembling and cleaning;

Motor is installed with overload protection and safe switches for assuring safety.

-

Vertical Materials Mixing Machine

●Blades produced using special technology to make a barrel of uniform material mixing between 1 times faster than similar products;

●The barrel body applies taper bottom with profile modeling Blades, instantly and evenly mix materials with high efficiency;

●Mixing Blades and the barrel body are made of stainless steel, the Blades can be removed for maintenance, thus prolonging the service life;

●Profile modeling closed mixing, high capacity, convenient operation;

●Directly drive with motor, drop power consumption without sliding;

●The mixing time is set according to actual requirement, timing stop. -

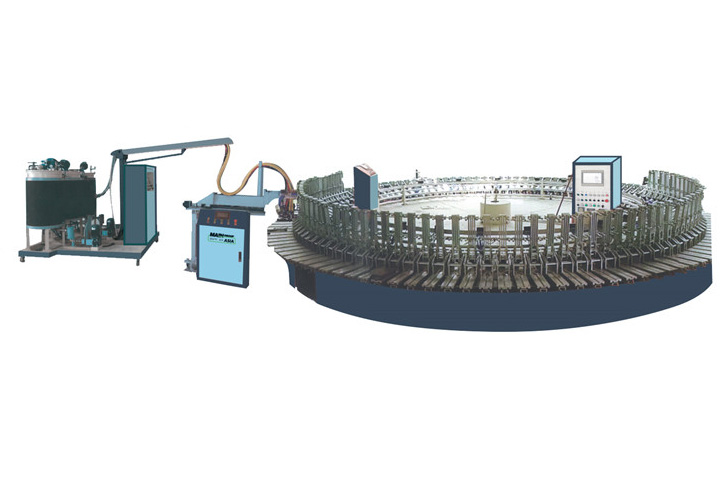

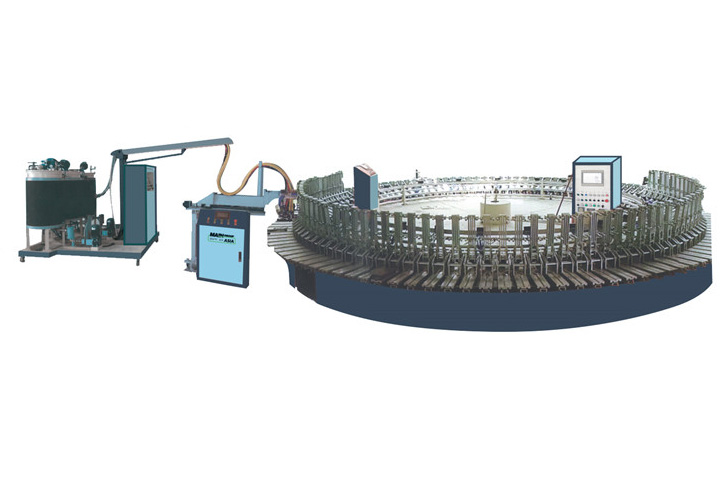

MGPU-800L Rotary(Disc-Belt)Production Line

● Labor Saving Energy Saving;Long Service Lifeand Stable Operation.

● According To The Space Limitation To Design The Output,Min Diameter 5m,Max Diameter14m.

● Wide Application Change Different Mold Die Set Can Produce Different Products.

● Easy Operation,Maintain Convenience,Workshop Cleaning,Small Floor Area Occupied

● Rotary Automatic Transfer,Robot Automatic Pouring,Auto-Switch Mould,Automatic Spray Mold Release Agent,Etc.,High Degree Of Automation. -

Full Automatic double colors EVA foaming injection moulding machine

Function:

● Low Operation Height

● Operation Height In Accord With Human Engineering

● Extra Height Opening Stroke

● Mold Opening Stroke 350mm

● Extra Mold Clamping Force

● 2000kn

● Rapid Mold Opening

● Use The Crank-Type Institutions Instantly Open Mold

● Saves The Electrical Energy 30%

● Hydraulic Servo System Energy Saving -

ETPU1006 Popcorn Automatic Molding Machine

● Equiped With Self-Research Full Automatic Operation Systern,Without Manulaction ● For Open-Close Progress,It Can Achieve Heating And Coling Automatic Open-Close

● To Production,Reduce The Labor Cost And Work Intensity

● Adopt Plc Controling System, Touch Screen Display, Easy To Operate And Learn .

● With Cold-Water Cooling System,Highly Improve The Cooling Effect.

● Enclosure Type Operation,Save And Reliable. -

SP55-3 Static Machine For The Production One Color Sole In Thermoplastic Macterials

The production is suitable for various types of shoes, made of compressed and expanded thermoplastic materials, with or without embedded monochrome soles (leather bottom, sandwich, heel belt, etc.) static injection molding machine. It represents the best choice of static injection molding machine for monochrome soles. Because it effectively solves all kinds of problems of this kind of products, the diversity of types, colors and materials requires the machine to have a strong flexibility. Operation Principle The machine uses a squeeze jet system. Extruder motors with three speeds or as optional are available for screw – one – piston injection and hydraulic motors. The machine consists of 3 workstations, either manual or semi-automatic with extractor

(Optional). Propulsion is pneumatic or hydraulic (optional). The simple structure, strong and flexible composition of the parts enables this series of products to be adapted to a variety of production requirements, while ensuring the highest quality and labor productivity in a variety of working environments.

-

RB1062 Automatic Rubber Injection Molding Machine

1. The Movement Mechanism Is Under The Gear Transmis-Sion Computer Digital Control,Stable In Movementandaccurate In Positioning.

2. The Mold Clamping And Locking Mechanism Is In Au-Nique Structure Format With Greater Mold Clamping Andlocking Force, Fora Niceappearance Of Products With-Out Flashes And Burrs.

3. The Mold Rolling Mechanism Is Safe And Reliable,Keasy To Removeand Change A Mold,With Alarge Spacefor Operation.

4. In A Reasonable Design,Easy To Install,Small Volandspace.

5. Compliant With Humanized Design,Easy To Operate,Au-Tomatic Mold Opening&Closing,Saving Labor Cost.

6. Adopting Intelligent Man-Machine Interface And Plcprogramn Control,With Precise Measurement. -

BS150 Staic Machines For The Production Of One/Two-Colored Soles In Thermoplastic Macterials

With 35 Years Of Experience In The Field Of Static Machines, Andnearly 5000 Units Soldin The World,Global Bs/150 Is The Resultofa Successful Research Aimed At The Cost Production And Market-Ing Orientation. Global Bs/150 Mainlyincludes Two Types Extrud-Er And Screw-Piston, For The Production Of One Or Two Coloredsolesln All Kinds Of Thermoplastic Materials(Tr,Tpr,Pvc,Tpu).

-

BS220 Staic Machines For The Production Of One/Two-Colored Soles In Thermoplastic Macterials

With 35 Years Of Experience In The Field Of Static Machines, Andnearly 5000 Units Soldin The World,Global Bs/150 Is The Resultofa Successful Research Aimed At The Cost Production And Market-Ing Orientation. Global Bs/150 Mainlyincludes Two Types Extrud-Er And Screw-Piston, For The Production Of One Or Two Coloredsolesln All Kinds Of Thermoplastic Materials(Tr,Tpr,Pvc,Tpu).

-

MG-112LA Intelligent Automatic Disc Type Continuous State Shoe Injection Molding Machine

● Last Intelligent Recognition Signals Ensure The Personal Safety Of Operators; Open And Close Mold Working Position Can Be Freely Selected By Computer Control,

● Which Can Produce A Variety Of Functional Shoes;

● It Can Be Divided Into One And Two Times, To Ensure That The Shoe Shape Is Not Deformed;

● Equipped With Mold Cooling Function, To Ensure That The Product Shape Better Without Deformation;

● Material Barrel Is Better In Plasticization, Pvc Foam Is Lighter And More Uniform, Can Be Modified Tpu, Artificial Rubber;

● Full Intelligent Touch With Power Display Temperature, Temperature Accuracy Is Higher. -

YZ-660 Automatic Rubber Injection Molding Machine

● The Movement Mechanism Is Underthe Gear Transmission Computer Digital Control,Stable In Movementand Accurate In Positioning.

● The Mold Clamping And Locking Mechanism Is In Au- Nique Structure Format With Greater Mold Clamping And Locking Force, For A Nice Appearance Of Products Without Flashes And Burrs.

● The Mold Rolling Mechanism Is Safe And Reliable, Keasy To Remove And Change A Mold,With A Large Space For Operation.

● In A Reasonable Design, Easy To Install,Small Voland Space.

● Compliant With Humanized Design, Easy To Op Erate, Automatic Mold Opening&Closing,Saving Labor Cost.

● Adopting Intelligent Man-Machine Interface And Plc Programn Control, With Precise Measurement.